This summer, I had the opportunity to participate in an annual business review which was conducted by one of Milwaukee Electronics’ key electronics manufacturing customers. Read More

Milwaukee Electronics has now installed and is utilizing two new SMT lines. The equipment was installed at our Tecate, Mexico and Portland, Oregon electronic manufacturing facilities. Read More

This week, our Portland Oregon facility is installing a new SMT production line. We’ve invested in new Panasonic SMT Equipment, which is state of the art and highly efficient; especially in High Mix Low Volume (HMLV) environments! Read More

From all of us at Milwaukee Electronics, we wish you the best this holiday season. Our latest company newsletter highlights the new happenings in Milwaukee Electronics and how we are improving to better serve our customers. Read More

Mexico continues to remain a strategically competitive geographic location for North American businesses seeking a cost-effective, high quality manufacturing and assembly solution for product production. From the standpoint of an electronics manufacturing services provider like Milwaukee Read More

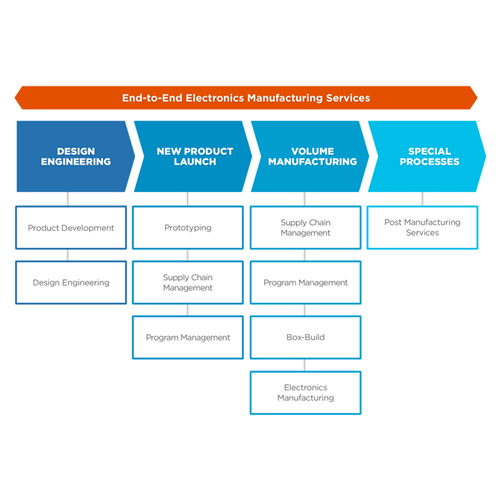

In modern-day electronic manufacturing environments, business models must evolve and change in order to adequately solve complex customer challenges and create robust solutions. The past three years at Milwaukee Electronics have influenced important changes to our own business strategy in accordance with these Read More

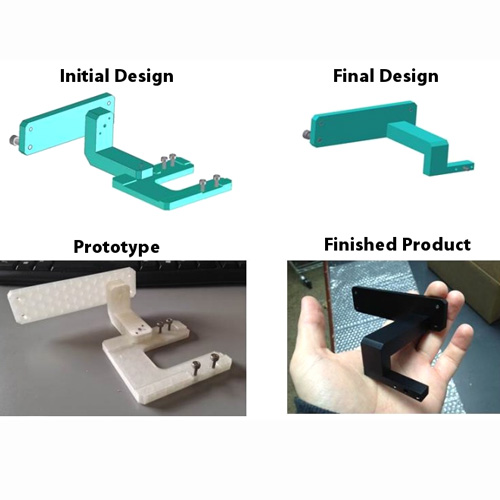

Here at Milwaukee Electronics, our Design Engineering Group regularly solves significant challenges our customers face for their electronics design and PCB layout projects – but we don’t stop there. Read More

Milwaukee Electronics began to develop electronics manufacturing solutions for our customers over 60 years ago. Back in 1954, the bourgeoning world of PCB Read More